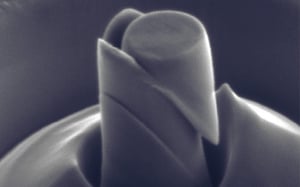

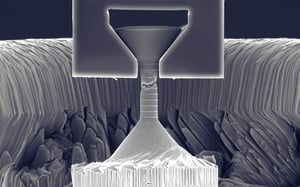

Fracture toughness is a key materials property in many engineering applications. Conducting fracture experiments at small scales allows you to measure the individual contributions of specific microstructural features to a material's overall crack resistance. This is typically accomplished using micro-cantilever fracture tests by applying compression to notched cantilever beams, meticulously prepared using lithography or a Focused Ion Beam (FIB). Using continuous stiffness measurements or in-situ SEM (Scanning Electron Microscopy) observation, the crack extension can be directly monitored during the test. This provides valuable insights into the fracture mechanisms within the specific microstructural feature of interest.

Application Examples

- 01 Fracture Toughness

- 02 Strength of Interfacial Bonds

Fracture toughness: The J-integral method

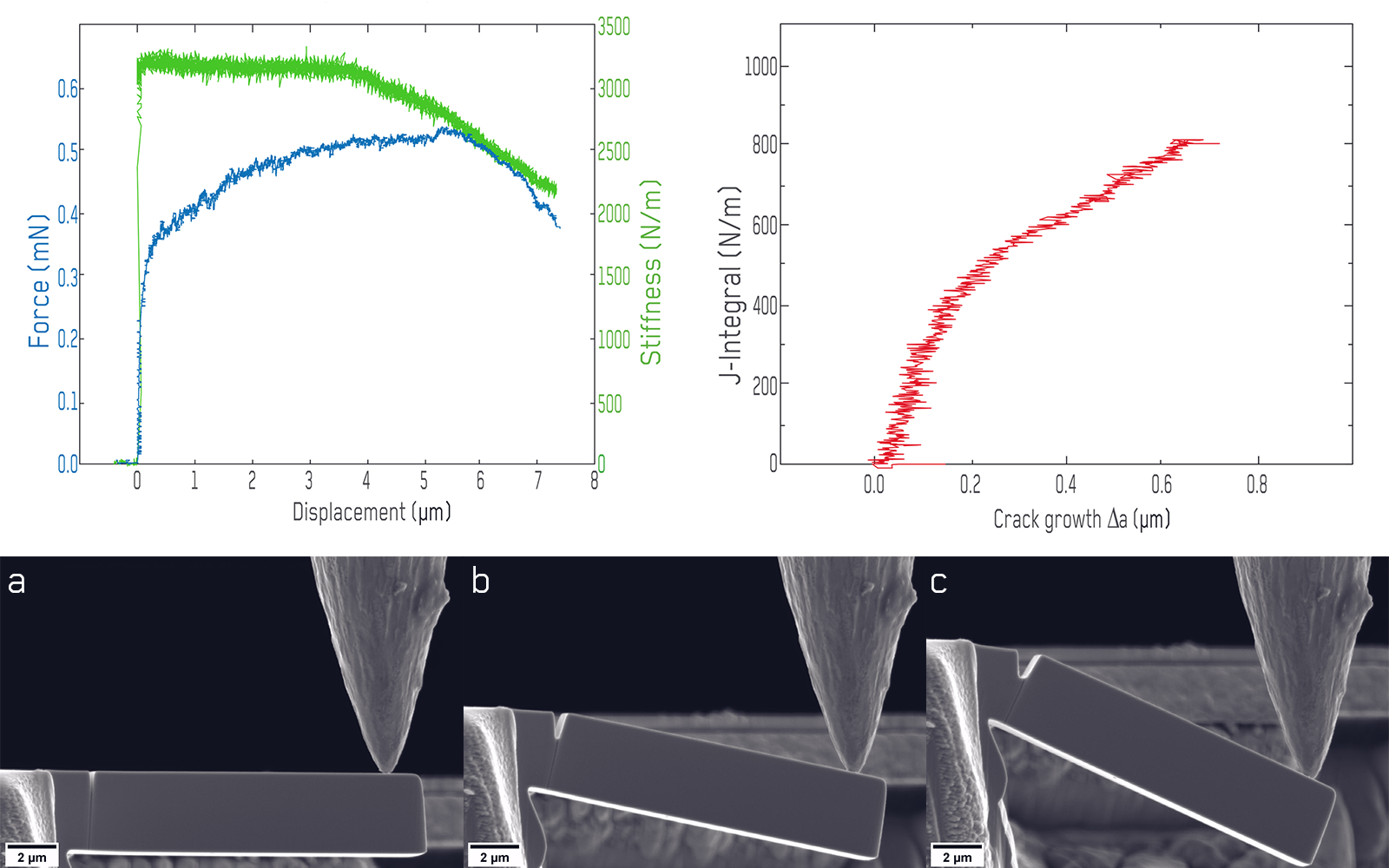

For brittle fracture, the fracture toughness K1C is determined from the stress intensity factor K at the maximal load. To prevent premature failure and ensure a reliable measurement, displacement control is essential to prevent overloads during any initial yield events. This approach mitigates the risk of catastrophic failure of the specimens when the crack becomes unstable—a common complication with force-controlled systems.

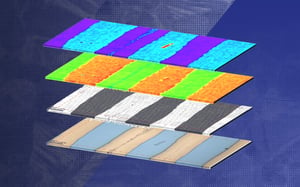

In tougher materials, elastic-plastic fracture mechanics is needed. In this case, the J-Integral serves as the pivotal fracture parameter, facilitating the evaluation of the crack growth resistance curve (J-R curve) and the elastic-plastic fracture toughness (J1C). In this application example, micro-cantilever bending tests using continuous stiffness measurement (CSM) are use to provide simultaneous monitoring of crack length evolution and measurement of a continuous J-integral through periodic unloading segments. Typically, higher values of K1C, J1C or a steeper J-R curve are indicators of a material's enhanced resistance to fracture.

Strength of the Interfacial Bond between Silica-inclusions and Iron

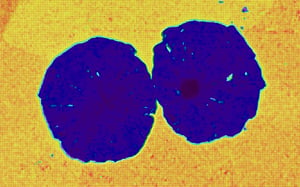

In steelmaking, incorporating elements like Si, Al, Ca, and Mn is common to prevent effervescence. However, during cooling, diverse non-metallic inclusions (NMIs) form and impact the alloy's properties. Despite these oxide inclusions typically being detrimental, "inclusion engineering" strives to turn their unavoidable presence into an advantage.

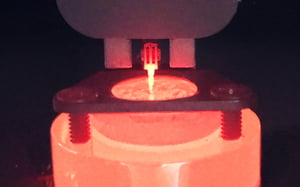

In this application example, the interfacial strength between iron (Fe) and silica inclusions was measured by means of in-situ SEM micro-cantilever bending tests. The results suggest that the presence of silica inclusions does not compromise the mechanical properties of iron-based alloys at room temperature.

Nanoindentation

READ MORE ->

Read More

Micro-Pillar Compression

READ MORE ->

Read More

Micro-Tensile Testing

READ MORE ->

Read More

High-Temperature Testing

READ MORE ->

Read More

Mechanical Microscopy

READ MORE ->

Read More

Correlative Mechanical Microscopy

READ MORE ->

Read More

Scratch Testing

READ MORE ->

Read More

Simultaneous Mechanical Testing with STEM/EBSD

READ MORE ->

Read More