Time is money. Ensuring the most consistent and accurate measurements requires that experimental variables, including the indentation strain rate, are held constant between experiments.

While holding displacement rates constant achieves much more consistent results between materials of different hardnesses than constant loading rates, testing at constant indentation strain rates (h’/h) achieves the highest level of consistency.

Strain rate control also allows the influence of strain rate on mechanical behavior to be directly investigated. Strain Rate Jump (SRJ) testing further enhances this by changing strain rates within a single test, enabling faster and more consistent measurements of rate sensitivity within a single indent.

Application Examples

- 01 Constant Strain Rate Indentations

- 02 Strain Rate Jump Indentations

- 03 Strain Rate Jump Mapping

Constant Strain Rate Indentations

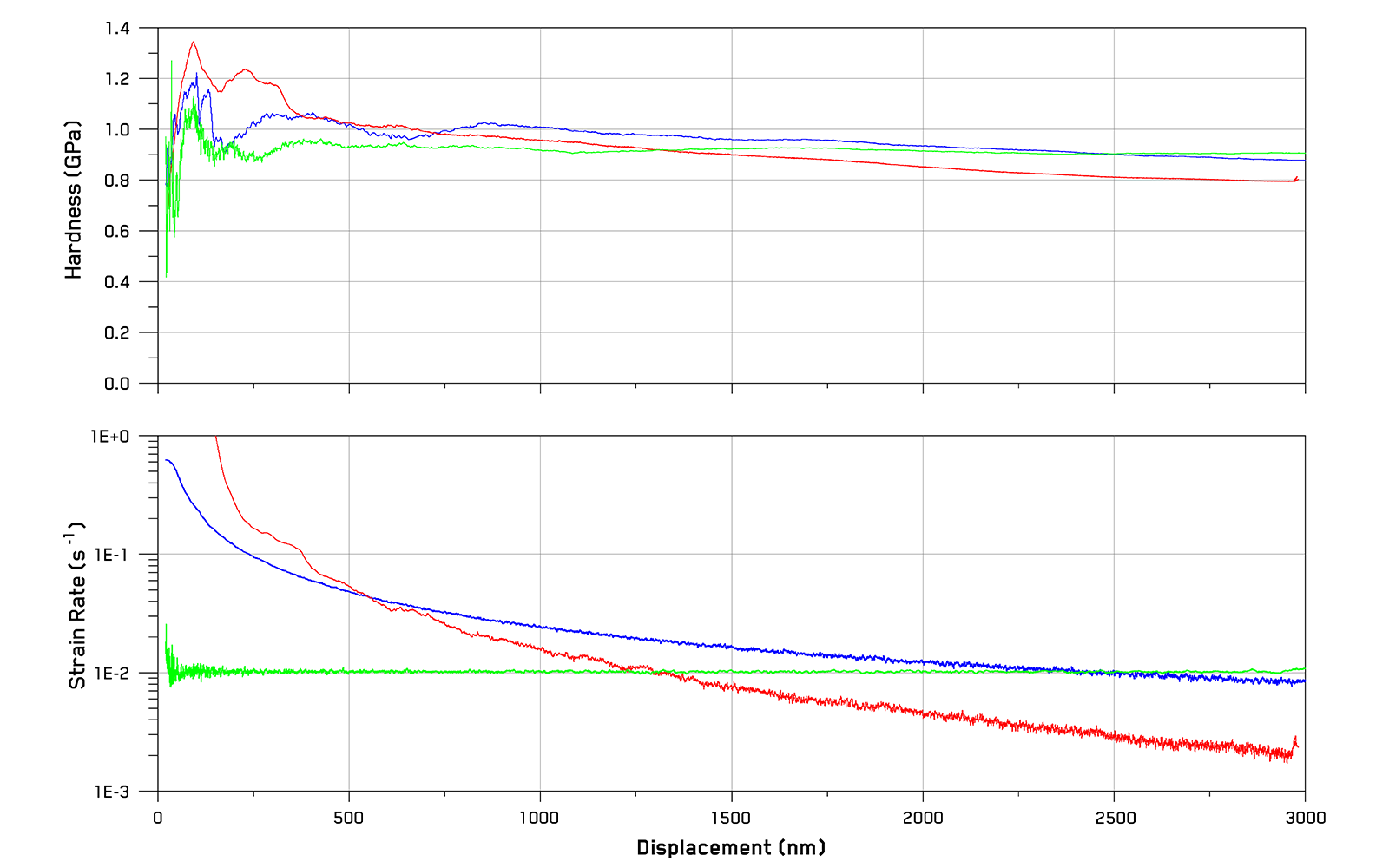

Strength depends on the speed of deformation. The control mode used to perform nanoindentation has a large influence on the speed of the normalized deformation (strain rate). A constant loading rate (CLR) produces a very high initial strain rate at low indentation depths that rapidly decreases with depth. Constant displacement rate (CDR) tests produce a similar but less depth-dependent trend.

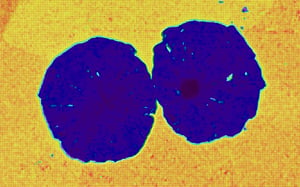

In this example, the relationship between control modes and indentation strain rate is demonstrated on ultrafine-grained aluminum. CLR and CDR tests give varying hardness values with depth, depending on the strain rate. Constrain strain rate (CSR) indentation produces a consistent value independent of depth.

Strain Rate Jump Indentations

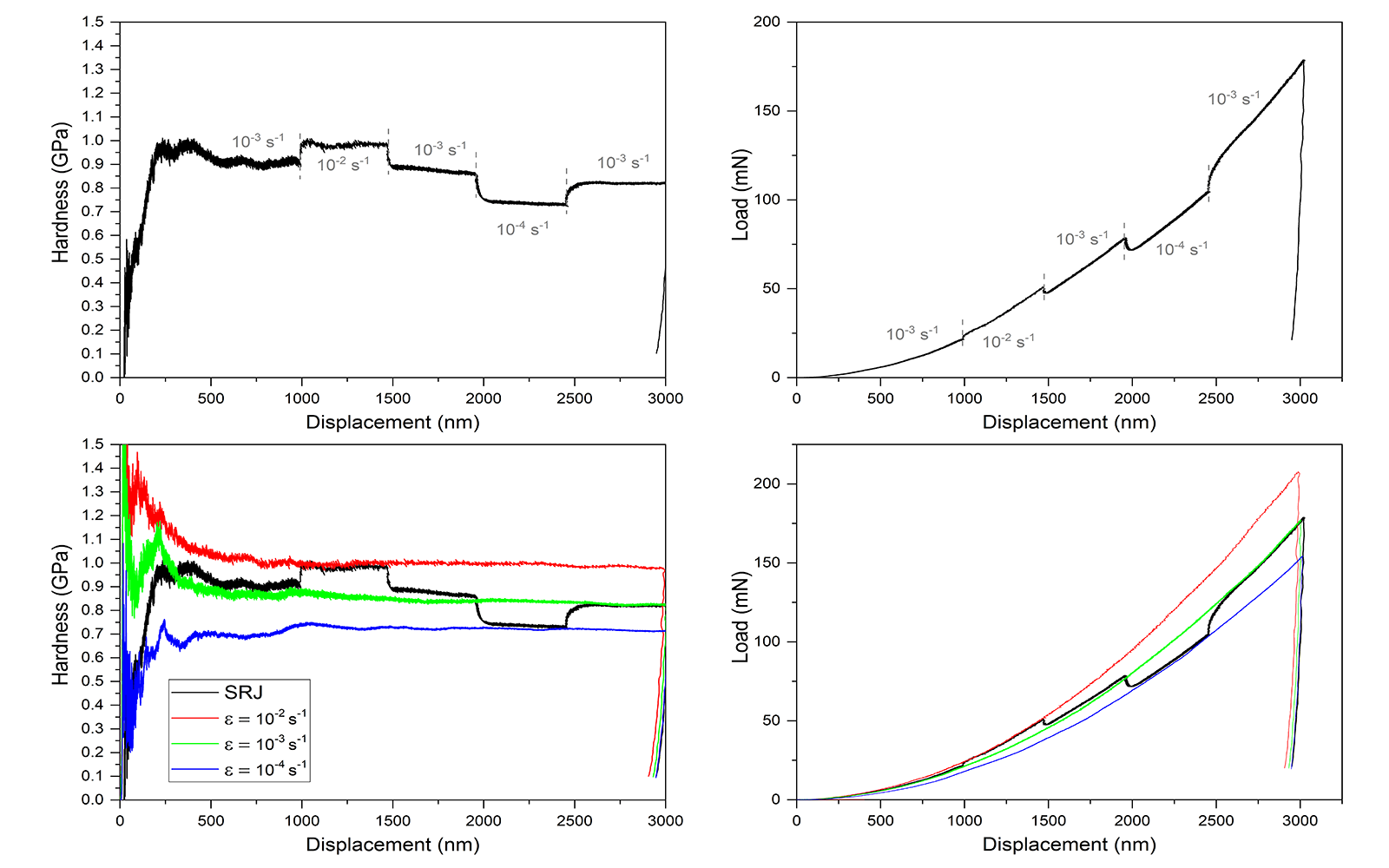

The native displacement control of FemtoTools systems provides a huge benefit for strain-rate controlled testing. As the indentation strain rate (h’/h) is a direct function of the displacement rate, this can be easily changed during a single test to measure the strain rate sensitivity (SRS) of a material. This is called strain rate jump (SRJ) indentation.

In this example, SRJ indentation is performed on ultrafine-grained aluminum, which has high rate sensitivity due to its sub-micron grains. Hardness plateaus with depth during each strain rate jump correspond to their constant strain rate equivalent tests. SRJ testing provides both faster and more consistent measurements of strain rate sensitivity.

Strain Rate Jump Mapping

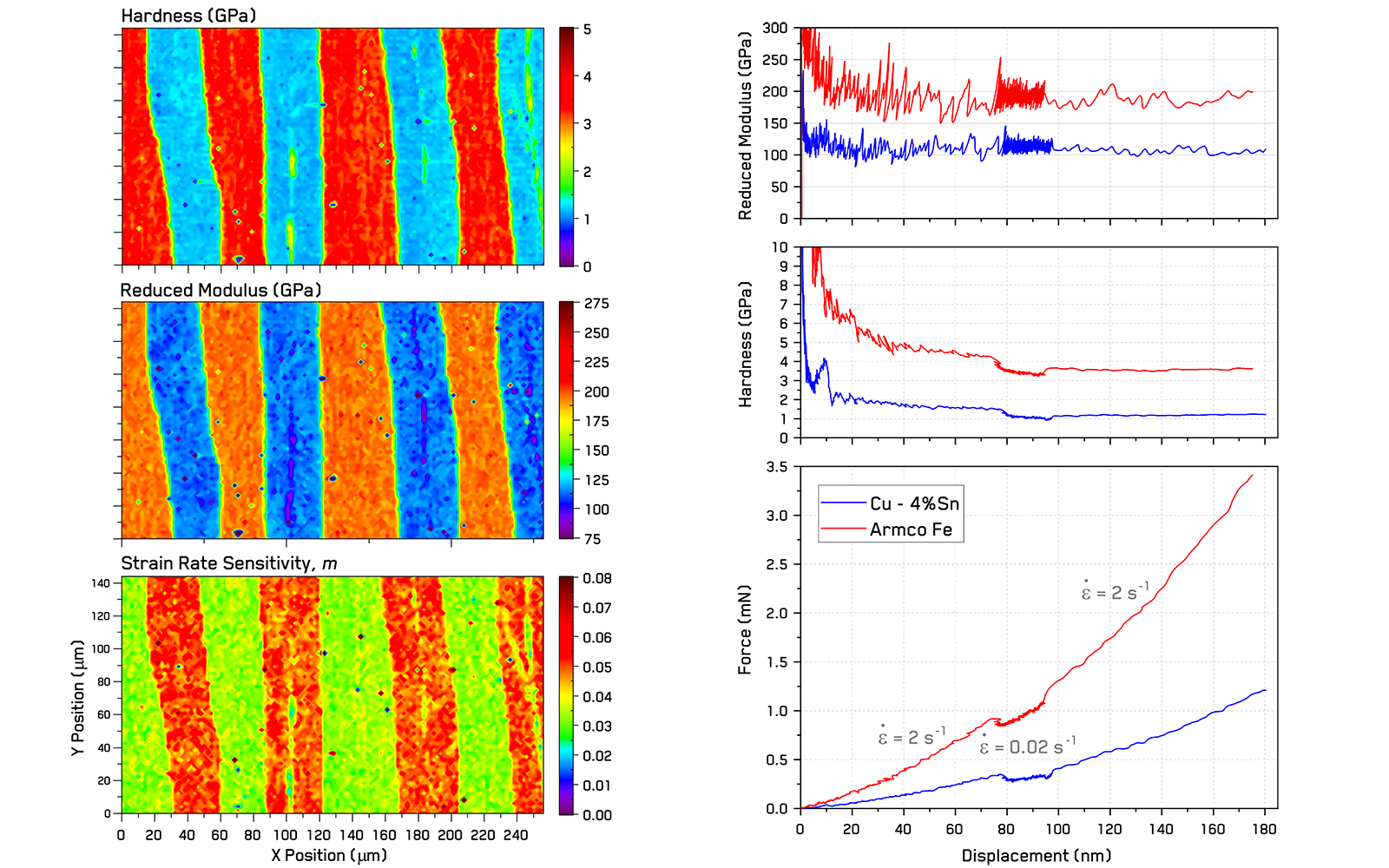

Why stop at single SRJ indentations, when you can map local properties with them too? The unique combination of FemtoTools’ high speed dynamics and native displacement control allows you to perform strain rate jump indentations - fast.

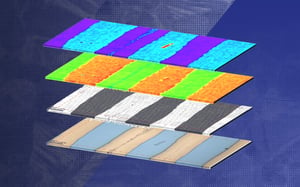

In this example, the strain rate sensitivity of the phases within an Iron-Bronze laminate material manufactured by accumulative roll bonding (ARB) is mapped using high-speed strain rate jump indentations. This provides statistical measurements of each phase’s strain rate sensitivity and insight into their deformation mechanisms and activation parameters.

Application Notes

Strain Rate and Nanoindentation

Nanoindentation

READ MORE ->

Read More

Mechanical Microscopy

READ MORE ->

Read More

Correlative Mechanical Microscopy

READ MORE ->

Read More

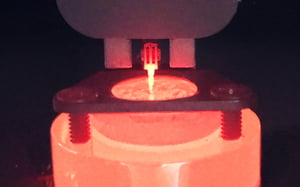

High-Temperature Testing

READ MORE ->

Read More

Scratch Testing

READ MORE ->

Read More

Soft Materials Testing

READ MORE ->

Read More

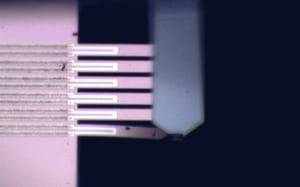

MEMS Mechanical Testing

READ MORE ->

Read More

Micro-Pillar Compression

READ MORE ->

Read More