Scratch testing is one of the oldest methods for assessing hardness and is also among the least well-understood. This is primarily due to the complexity of the stress states at the tip. However, perhaps all that is needed is a more comprehensive view.

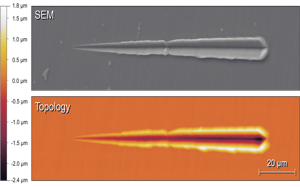

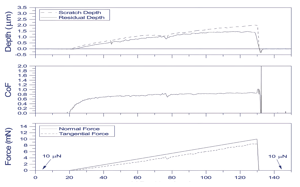

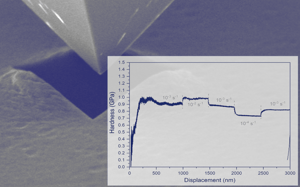

With the use of new nanoindentation tools, it is now possible to clearly visualize deformation processes during scratch testing, while simultaneously measuring depth, normal and lateral forces, coefficients of friction, and acquiring pre- and post-scans of surface topology. This advancement brings scratch testing firmly into the toolkit of the modern materials scientist.

Application Examples

- 01 Tribological Assessment

- 02 Friction Analysis

- 03 Scratch of Coatings

Tribology and Chip Formation

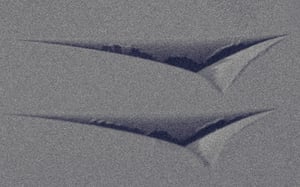

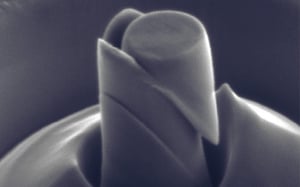

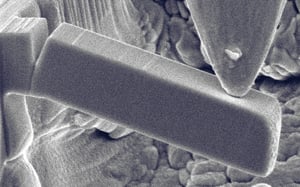

Scratch testing plays a crucial role in understanding wear mechanisms in tribology, specifically abrasion and erosion processes, as well as offering insight into chip formation during machining. Through observation of various materials deformation behaviors (e.g. plastic slip, grain rotation and pile-up, shear banding, extrusion, and cracking), we gain valuable technical knowledge.

In this application example, an aluminum single crystal (SX) demonstrates smooth deformation, highlighting the importance of slip planes, while ultra-fine grained (UFG) aluminum exhibits a textured chip, indicating the movement of individual grains. Additionally, bulk metallic glass (BMG) and Al-Cu eutectic alloy samples display unique deformation patterns, like serrated flow and local scratch hardness variation, respectively.

| 0.5 nN Force resolution |

100 kN/m Sensing element stiffness |

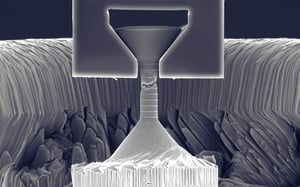

Effects of Material Imperfections on Cutting Resistance and Surface Friction

Nothing is perfect, especially in engineering materials, where 'imperfections' like grain boundaries can enhance an alloy's strength.

In situ videos and scratch data illustrate how the Cube Corner diamond tip interacts with defects and inclusions in samples, affecting chip formation and causing machining chatter.

The aluminum 5052 marine alloy’s inclusion reduces penetration depth and increases friction significantly, while the bulk metallic glass (BMG) shows lower scratch resistance, evidenced by serrated flow due to shear banding under higher loads

| 0.5 nN Force resolution |

100 kN/m Sensing element stiffness |

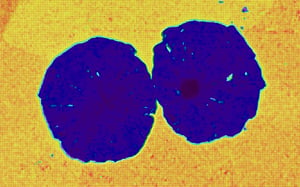

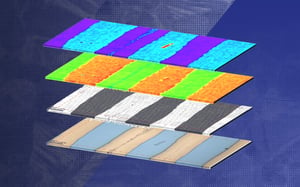

Overcoming Industrial Scaling Challenges for MoS2 Solid Lubricant Coatings

Molybdenum disulfide (MoS2) is a popular solid lubricant coating used in various industries, particularly in applications where traditional liquid lubricants may not be suitable. They are commonly used for providing dry lubrication in bearings under challenging environmental conditions, e.g., vacuum, high load, and irradiation.

However, industrial upscaling frequently results in a different coating microstructure than the laboratory prototypes presented in the literature.

Therefore, to ensure full functionality in these coating systems, the coatings must be cohesive and well-adhered to their substrate, whether that is another coating, a silicon wafer, or precision optics.

| 0.5 nN Force resolution |

100 kN/m Sensing element stiffness |

Application Notes

Nano-Scratch Testing of Thin Films

Nanoindentation

READ MORE ->

Read More

Mechanical Microscopy

READ MORE ->

Read More

Correlative Mechanical Microscopy

READ MORE ->

Read More

Strain-Rate Control

READ MORE ->

Read More

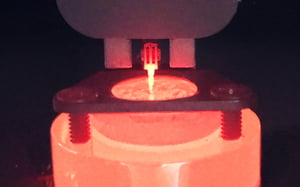

High-Temperature Testing

READ MORE ->

Read More

Micro-Pillar Compression

READ MORE ->

Read More

Micro-Cantilever Testing

READ MORE ->

Read More

Micro-Tensile Testing

READ MORE ->

Read More