Polymers, foams, aerogels, and bio-inspired substances like hydrogels are often classed together as Soft materials. These highly-deformable materials have many unique mechanical behaviors like viscoelasticity and excellent damping.

Understanding their mechanical behavior is crucial for biomaterials and life sciences and their applications in health-related and medical fields.

The ‘softness’ of these materials means that large displacements are made even with very small forces. FemtoTools meets this challenge with its industry-leading force resolution and long-range displacement capabilities.

Application Examples

- 01 Compression of Hydrogels

- 02 Tensile Test of Fibers

- 03 Biological Applications

- 04 In-Liquid Testing

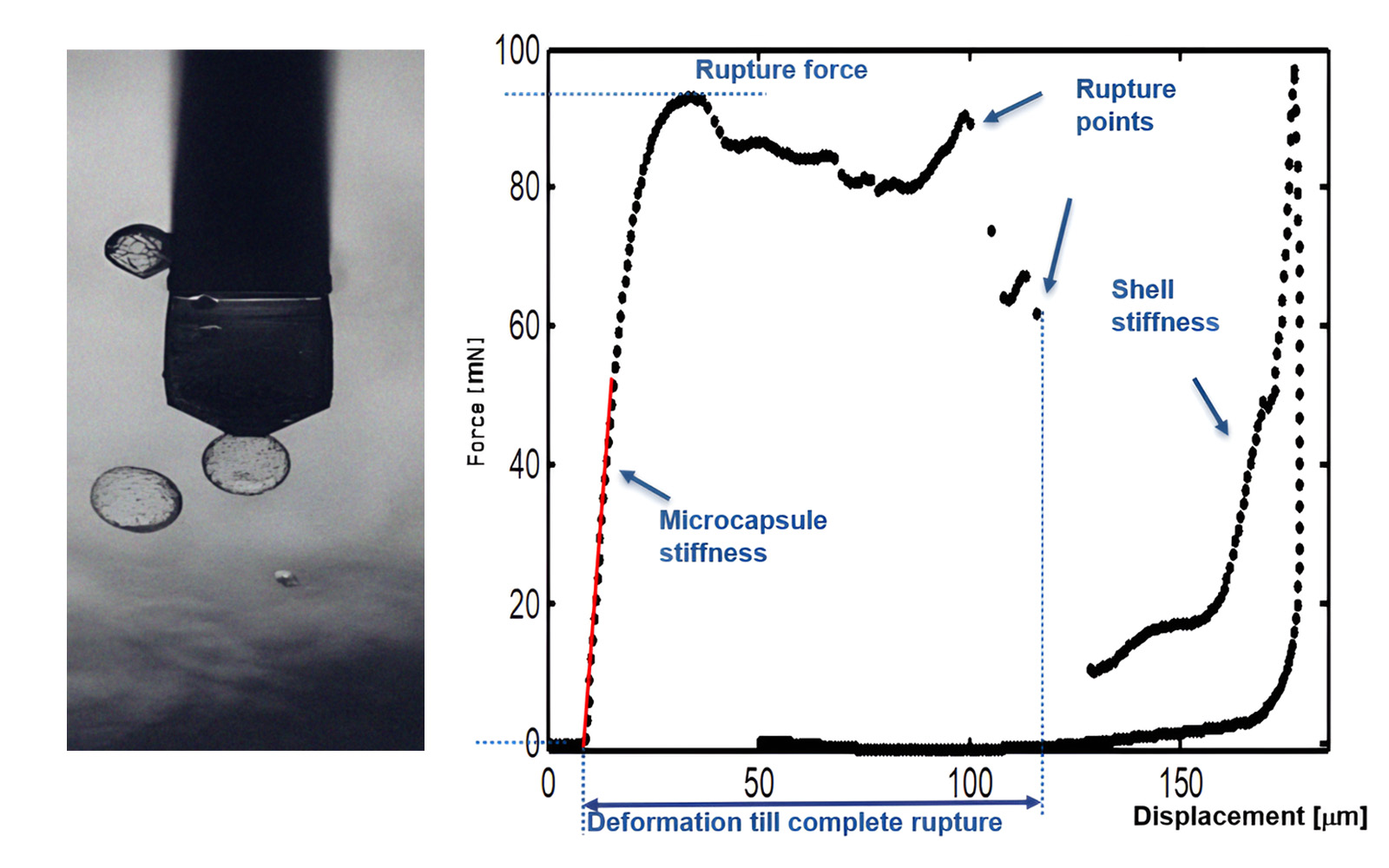

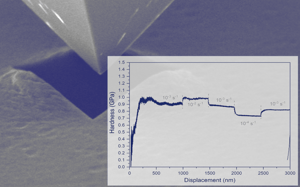

In-liquid compression and fracture of hydrogel microcapsules

Hydrogel microcapsules are carriers for drug delivery. They are designed to encapsulate drugs and facilitate targeted release within the body, enhancing therapeutic outcomes.

Mechanical testing of hydrogel microcapsules is crucial for ensuring their effectiveness in drug delivery. It helps predict their behavior in biological environments, optimizing delivery precision and minimizing adverse effects.

In-liquid compression testing, coupled with side-view microscopy, reveals the various deformation stages and rupture forces. This method offers insights for refining drug delivery systems, crucial for improving patient outcomes.

Tensile Test of Micro-fibers

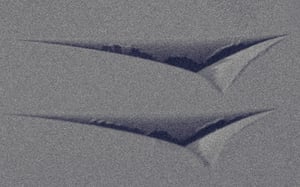

Microfibers are used to reinforce composites & optical fibers and to create strong, lightweight components. To understand their mechanical behavior, micro-tensile testing is the ideal method.

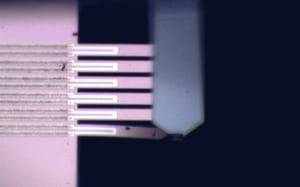

In this application example, silica microfibers produced using roller electrospinning are investigated using micro-tensile testing. The fiber is gradually stretched until it becomes straight and then further elongated to measure its maximum elongation, maximum yield strength, and stiffness. Relaxation behavior and cyclic testing was also performed, providing insight into the durability and application potential of the silica fiber.

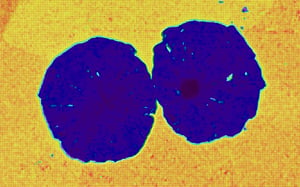

In-Liquid Micro-scale Testing of Plant Root Hairs

How do plants grow? To understand the mechanics of root growth in soil, micro-tensile testing was applied to delicate plant root hairs to measure their tensile strength, yield strength, and other properties.

This application example revealed that upon loading, root hairs partially fracture and form a helical shape, instead of failing completely. These observations offer valuable insights into the mechanical and structural behavior of plant root hairs, with potential implications for biology, agriculture, and materials science.

In-Liquid Tensile Testing of Fibronectin Fibers

Fibronectin (Fn) fibers are crucial for wound repair, a critical application in medicine and healthcare. Using tensile testing in a simulated physiological environment, the mechanical properties of Fn fibers can be determined in the laboratory before human trials.

In this application example, the folding and unfolding mechanisms of Fn fibers were observed by deploying them on microfabricated PDMS grids, rehydrating them in PBS buffer, and applying micro-tension. This innovative approach blends biology and engineering to offer insights into the functions of biological materials, paving the way for advancements in healthcare solutions.

Nanoindentation

READ MORE ->

Read More

Mechanical Microscopy

READ MORE ->

Read More

Correlative Mechanical Microscopy

READ MORE ->

Read More

Scratch Testing

READ MORE ->

Read More

MEMS Mechanical Testing

READ MORE ->

Read More

Strain-Rate Control

READ MORE ->

Read More

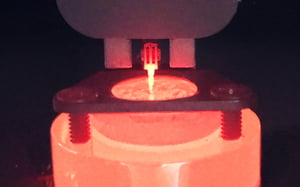

High-Temperature Testing

READ MORE ->

Read More