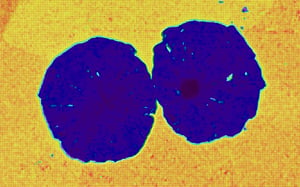

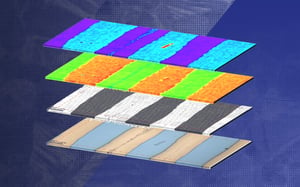

Materials are rarely composed of a single large crystal with perfect characteristics. Engineering materials are characterized by their designed microstructures, consisting of tailored grain sizes/distributions, defects, constituent phases, and precipitates. To fully understand the mechanisms behind a material’s mechanical behavior, delving into the small details is essential.

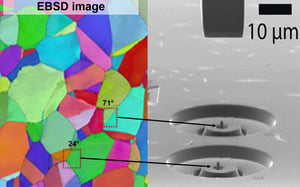

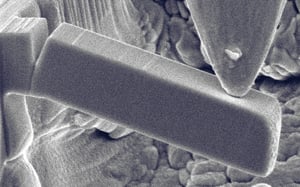

Micro-pillar compression tests enable the study of the mechanical response of specific constituents within a sample. By conducting standard micropillar compression tests at precisely-specified locations within the sample, it is possible to obtain not only the elastic modulus and yield strength at those locations but also to thoroughly investigate the failure mechanisms, and plastic response well beyond yielding.

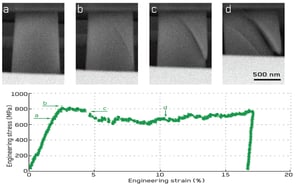

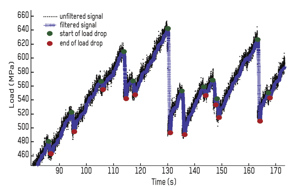

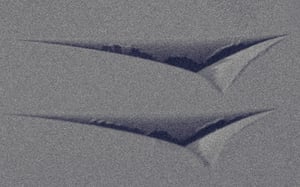

This application allows the measurement of flow strength and observation of phenomena like plastic flow intermittency, which is characterized by stress drops that accompany energy releases as the material transitions through critical states, and shear localization on various crystallographic planes.

Application Examples

- 01 Automated Testing

- 02 High-Temperature Testing

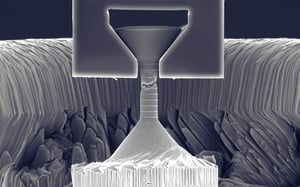

Automated Microcompression Testing

The introduction of Automated Statistical Microcompression Testing revolutionizes material science by transforming weeks of manual micropillar positioning into a swift 20-minute task.

This leap forward not only saves significant time but also enhances test precision and reliability, crucial for assessing materials' mechanical properties accurately.

Achieved through user-friendly software that simplifies setup and execution, this innovation streamlines research, fostering rapid technological and engineering advancements. It signifies a new era where efficiency and accuracy in material testing are seamlessly integrated.

| 10/minute Pillars compression rate |

Displacement controlled Intrinsic displacement control |

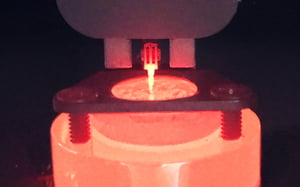

High-Temperature In Situ SEM Micro-Compression Testing

Incorporating high-temperature capabilities into in situ SEM micro-compression testing significantly enriches material research, especially in assessing performance under thermal stress.

This advancement allows for a granular examination of material plasticity and strength at micro levels under conditions that simulate real-world high-temperature scenarios.

Such detailed analysis is crucial for designing materials that operate in high-temperature environments, like turbine engines and electronic devices, ensuring they meet the demands of durability and thermal resistance.

| 800 °C Max test temperature |

Displacement controlled Intrinsic displacement control |

Nanoindentation

READ MORE ->

Read More

Micro-Cantilever Testing

READ MORE ->

Read More

Micro-Tensile Testing

READ MORE ->

Read More

High-Temperature Testing

READ MORE ->

Read More

Mechanical Microscopy

READ MORE ->

Read More

Correlative Mechanical Microscopy

READ MORE ->

Read More

Scratch Testing

READ MORE ->

Read More

Simultaneous Mechanical Testing with STEM/EBSD

READ MORE ->

Read More